Production

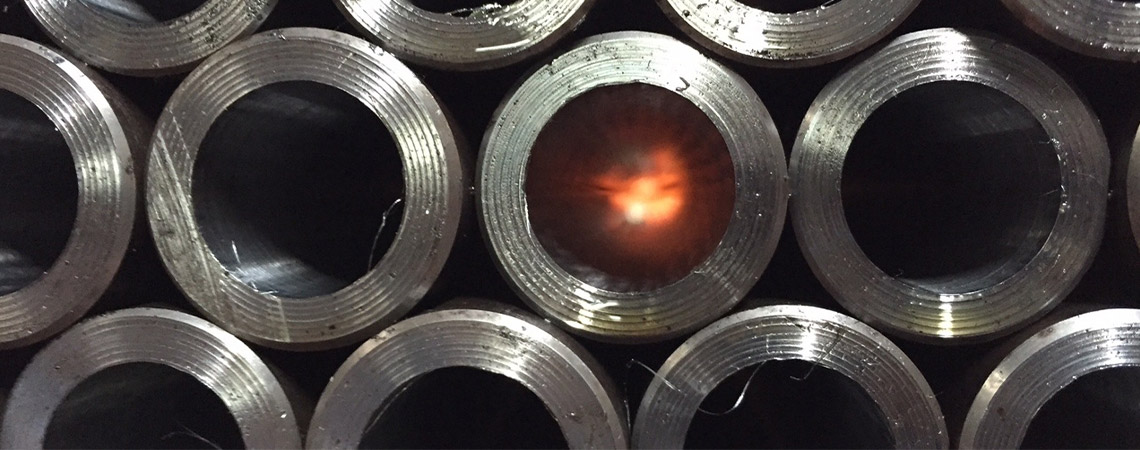

The work in the barrel department must ensure perfection of this most important part of the gun, to guarantee the highest possible level of performance by the finished gun. For this reason, the utmost care is taken in every single phase of construction and assembly, from the initial rough boring of the tubes, to soldering the ribs, to the absolutely critical final stage of straightening the barrel tubes, which is still carried out by the human eye, as no machine has yet proved better!

Every single component part of the guns is produced in our factory and must adhere to the most rigorous and precise technical specifications. The production of all these parts is carried out by the most modern and sophisticated CNC machines, with numerical control panels set to ensure the micrometric dimensions we require.

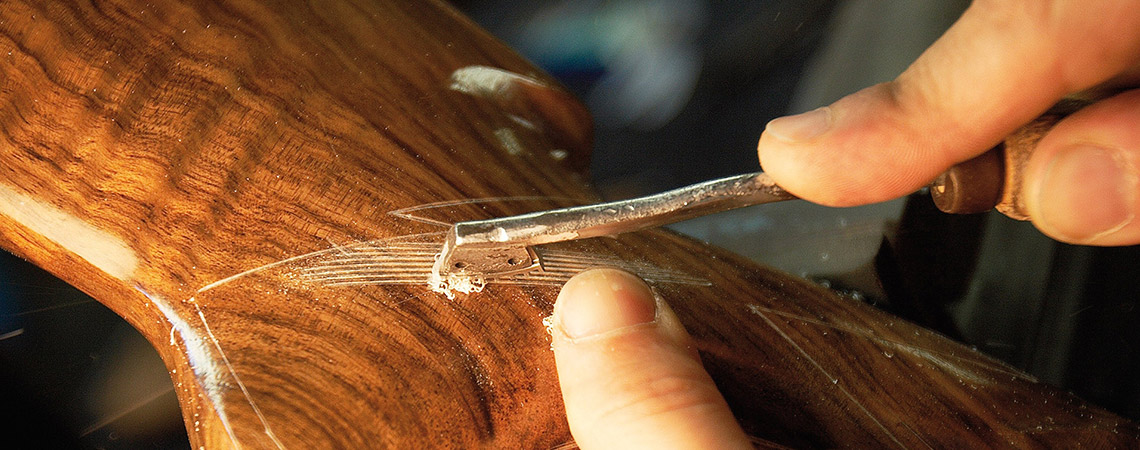

Stocks and forends are made of the finest quality walnut root from centuries-old trees, like the one in the photograph, with Daniele Perazzi and his wife Lucia. Each blank is carefully selected and classified individually. Before being made into stocks, the blanks are subjected to a long drying process. After that, our expert stock makers can create—in a few hours—custom stocks and forends, exactly matching the technical specifications and requirements of each shooter.

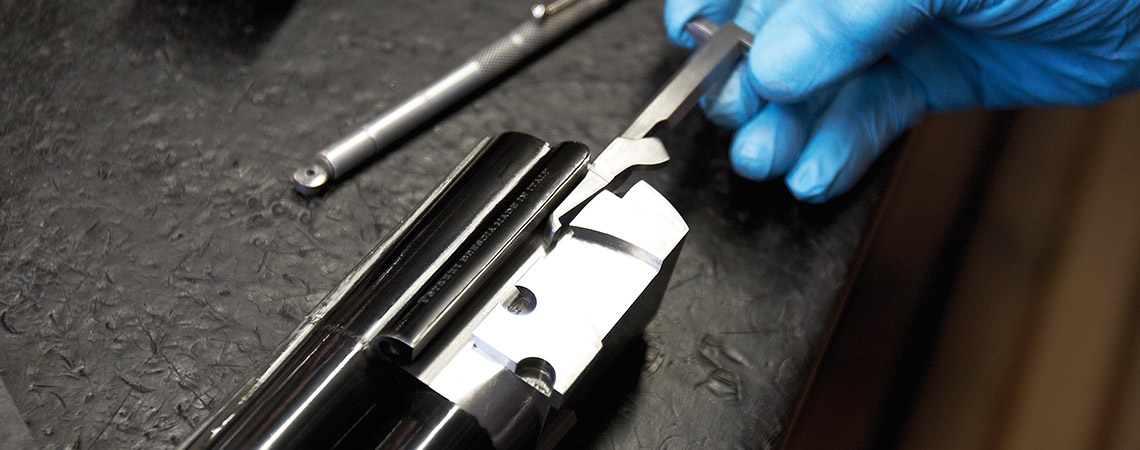

The assembly line is where the various components are brought together to create the finished gun. The careful hand-fitting of all parts is carried out by highly experienced gunsmiths, each specializing in his own area of expertise. Each phase of production - from initial serialization to the final inspection - is implemented with the sole aim of ensuring the completed gun complies exactly with the specifications requested by the client.